Durma AD-R 40.220 sheet bending machine

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

Germany

Germany

chamfer lenght 4050 mm

distance between columns 3600 mm

stroke of upper beam 265 mm

throat 410 mm

dayligth 530 mm

ajustment speed 160 mm/sec

working feed 10.0 mm/sec

return speed 140 mm/sec

Control DNC 880 S

work height max. 900 mm

table width 104 mm

back stop - adjustable max. 675 mm

oil volume 250 l

total power requirement 22.0 kW

weight 15600 kg

range L-W-H 5250 x 1770 x 2950 mm

** Current new price ~ 100.000 Euro

** Special price upon request

Equipment:

- CNC electro-hydraulic press brake

* Stress-relieved steel construction body = durable monoblock frame

- CYBELEC CNC control model DNC 880 S

* graphic display (extern)

* Product representation as line, area, or volume drawing

* Clear, user-friendly menus in the operator's language

* Extensive tool and product library

* Graphic 2D programming

* Automatic bending sequence calculation and collision detection

* Pivoting control panel, front right

- CNC-controlled axes: Y1 + Y2 + X + R axes + CNC crowning

- CNC electro-motorized backgauge (X axis)

* With 2 manually adjustable stop fingers (Z axis)

* Backgauge with ball screw + linear guides

* Travel speed .. 250 mm/sec.

- CNC electro-motorized height adjustment of the backgauge (R axis)

* Max. travel 250 mm

* Travel speed 140 mm/sec.

- CNC electro-motorized lower beam crowning

- FIESSLER laser safety device at the front

- Upper tool holder with upper wedge crowning + quick-change adapter (AMADA)

* Includes split tool set

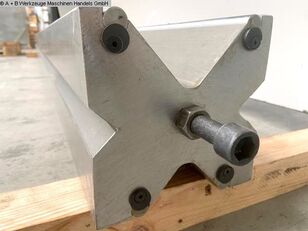

- 1x universally rotatable MULTI-V die block

- 2x front + sliding robust support arms

* Mounted on a linear guide rail system

- Side safety guard (swinging doors)

- Rear safety guard (swinging door)

- 1x freely movable foot switch

- Operating instructions (PDF)

The data for this ad was created with ModulMWS - the software solution of LogoTech oHG.

Hub der Oberwange 265 mm

Ausladung 410 mm

Zustellgeschwindigkeit 160 mm/sec

Arbeitsgeschwindigkeit 10.0 mm/sec

Steuerung DNC 880 S

Tischbreite 104 mm

Hinteranschlag - verstellbar max. 675 mm

Gesamtleistungsbedarf 22.0 kW

Gewicht 15600 kg

Abmessung L-B-H 5250 x 1770 x 2950 mm